Leading infrastructure consulting firm AECOM has professionals working in different regions across the world. That international experience of best practise is combined with local knowledge when a new design project is taken on.

AECOM brings global experience to the projects it delivers. When it comes to tunnelling, the company has professional specialists working in different regions across the world.

– We work together, and we share best practise and know-how. We have global knowledge of what works well, and lessons learned, which allows us to share and apply what we learn to all our projects, says Steve Woodrow, Global Practice Tunnelling Lead for AECOM.

AECOM’s ‘Think and Act Globally’ strategy is focused on extending the company’s industry-leading, global expertise to each of its projects around the world, and this has worked well in Sweden.

For example, for the Stockholm bypass tunnel, AECOM used a combination of tunnelling specialists from the UK, who brought technical expertise to the design, and local resources who brought local knowledge and understanding including ground conditions and construction support.

– We have almost 30 people in Sweden, working on multidisciplinary infrastructure projects. They bring valuable local experience, understand the market, and know our clients well. To that, we add our international expertise—and at times, we can bring in professionals from other regions to support projects, leveraging AECOM’s collective knowledge for the benefit of our clients. Still, the local team always leads and owns the project.

Encourage collaboration

AECOM delivers large-scale infrastructure projects and recognises that close collaboration is essential for success, with client, contractors and consultants working closely together.

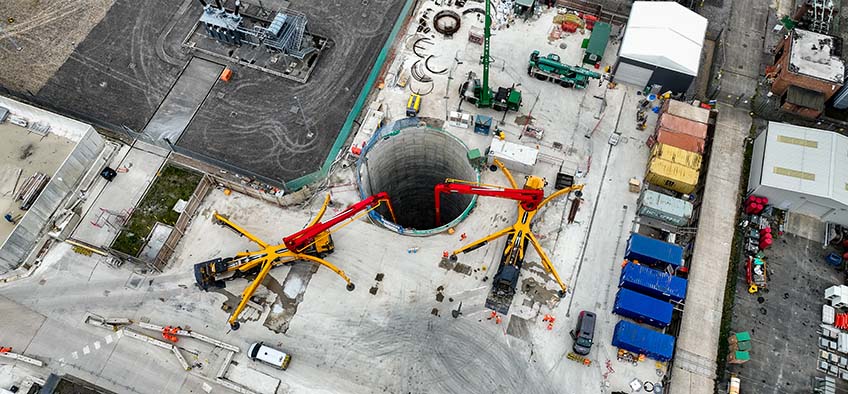

– Nowadays, large projects are often split into geographic or discipline-specific packages—or sometimes a combination of both. A good example is the London Power Tunnels Phase 2 (LPT Phase 2) scheme, where National Grid has split the scheme into six main works packages on a discipline basis. On LPT Phase 2 we are the lead designer, supporting HOCHTIEF-MURPHY Joint Venture (HMJV) on the Tunnels and Shafts package as well as the Headhouses and associated M&E Systems, says Steve Woodrow.

Package 1 covered the enabling works, Package 2 included all tunnels and shafts, Package 3 focused on the supply and jointing of the high-voltage cables and equipment, Package 4 is the installation of the HV cables, Package 5 is the Headhouses and the Mechanical and Electrical systems, and Package 6 covers the electrical substations.

– The end client, National Grid, did a great job of establishing a contract framework, utilizing the NEC contract as well as the Project 13 Enterprise philosophy, that encouraged cooperation among the various contractors delivering these packages.

Move work around

One strategy used to support this collaboration was the creation of an ‘enterprise pot’ —a shared pool of funding that allowed incentivization of performance and collaboration between contractors as needed. In addition, if a contractor was facing delays or challenges or if there were changing external requirements upon the scheme, tasks could be shifted between contractors to keep the overall project on track. Woodrow shares a concrete example in this regard from LPT Phase 2. “National Grid’s approach to collaboration allowed for work to be moved from one project package to another for the benefit of the project. For example, once the tunnelling works for Package 2 were complete, the permanent shaft cable support steelwork at some sites originally included in the cable installation package was transferred into the tunnelling package so as to provide project savings on programme as well as provide health, safety and sustainability benefits. National Grid’s approach to the packaging of the works and the contract encouraged this to happen. This approach not only saved valuable time and reduced pressure on individual teams, but also strengthened a collaborative, solutions-oriented mindset across the project.”

New ways of working

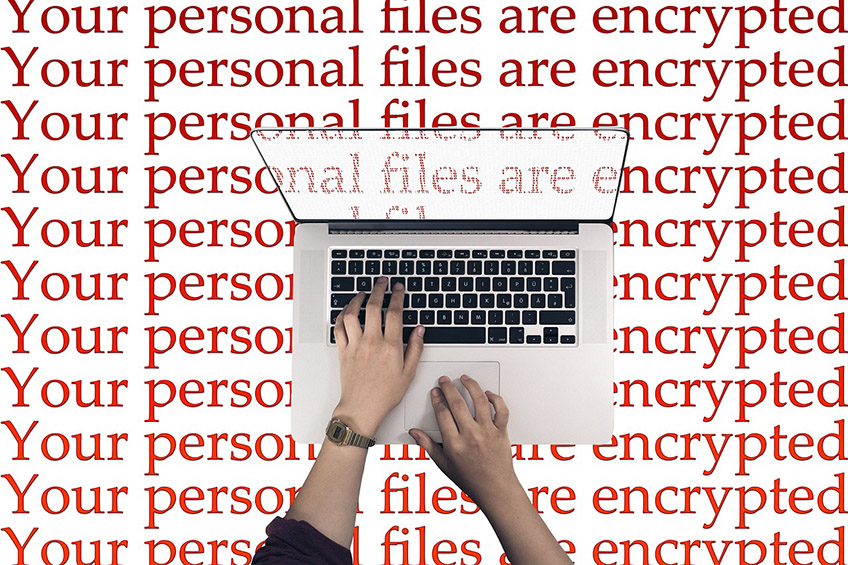

AECOM is committed to reducing carbon in its designs. Using low carbon materials is important in design, but there are also ways to minimise carbon in how you build.

– For example, some of the temporary works needed during a project can be built so that they become part of the finished structure. In addition to the environmental benefits, this approach can often also deliver a more efficient building process, claims Steve Woodrow.

He also points out that when excavating tunnels, there’s a lot of material that needs to be transported. Should it be done by road, by boat or by rail? Are there other alternatives or does it even need to leave the site? Can the excavated material be crushed and used in concrete or for landscaping on site?

– A lot of these solutions that are beneficial for the environment must be considered during the tender design phases. Early involvement is key to helping clients reduce the carbon footprint from the outset.” In the case of LPT Phase 2, AECOM worked collaboratively with National Grid, HMJV and other specialist partners (such as Wagners and OtB Concrete) to develop the use of low carbon alternatives to traditional construction materials. They undertook an extensive programme of trialling and testing of “Earth Friendly Concrete”, firstly for temporary works and then, following further technical review and testing, for permanent works, resulting in what is understood to be the world’s largest single continuous concrete pour of Earth Friendly Concrete for the shaft base slab at Hurst, saving over 80 tonnes of CO2 in the process.

Facilitate good cooperation

On complex projects involving multiple stakeholders, AECOM often operates as an extension to the client’s or the contractor’s team, frequently within a joint venture framework. This approach fosters close collaboration and seamless integration. In many cases —during site meetings, workshops or other collaborative settings— it can be difficult to distinguish between team members from different organizations, as everyone works together as one unified team. AECOM professionals integrate fully with partner teams to promote effective cooperation and ensure shared project goals are achieved. AECOM has developed its own model to manage its design work, which is then tailored to suit the specific needs of the project. In the case of the LPT Phase 2, a progressive design assurance approach was adopted. This approach includes a number of stages in the design process with hold points where all parties get to review and comment on the design proposals at key points. This allowed for increased certainty in the design and approval process and meant that the AECOM team met all of the delivery dates against what was a challenging programme.

– At each stage of the design, we invite all stakeholders into the conversation before we progress a design further. We present our concept to the client, the contractors, the operator and any other parties with a vested interest in the project. This helps to ensure alignment across the board and allows us to receive immediate feedback on our designs” tells Steve Woodrow.

Get questions in early

Creating these hold-points and prompting early questions reduces the risk of reworking later. This approach leads to more appropriate designs from the outset and enables a more efficient workflow for all project participants.

– As the project progresses, the number and impact of those questions naturally reduces. That gives us more certainty in delivery, says Woodrow. Building in these opportunities for questions and feedback is a valuable part of our design process that brings many benefits to wider project delivery.

For this approach to be effective, the right conditions need to be in place. That means a well-structured project led by a forward-thinking client, supported by collaborative and progressive contractors, and a culture that integrates all stakeholders as part of one cohesive team.

– Ultimately, our role at AECOM is focused on helping clients manage and mitigate risk, concludes Steve Woodrow. We do that by applying the right tools, engaging the right expertise, and creating the right environment to deliver projects on time and within budget —solving our client’s most complex challenges along the way.